- Drop Us An Email info@omcooling.in

- Toll-Free No : (24x7) 7669-293-885

- Get a Free Quote

The ducting system is typically a reliable, low-maintenance system in the overall building environment. Since there are no moving parts except the dampers, the maintenance is relatively affordable and not highly expensive. This is one of the reasons that the basic maintenance of the ducting systems is often neglected by the building maintenance teams.

But the reality is Ducting systems are in operation continuously, and there is no “backup” of the duct as other equipment and systems always have some alternative. The duct systems transport air to the occupants of the building and hence impact the well-being of all the users in your workspace. Ducting system is thus critical for business operation in any office or workplace. The key reason for the building maintenance team to keep duct maintenance a top priority are as follows:

Contamination of Air: The key types of contamination that can occur in the ducting system are:

Leakage of air : Dust systems are designed for a small amount of system volume leakage as the joints of the ducts are not airtight. According to the SMACNA standards they allow a 5% air volume leakage. But, Higher levels of leakage will result in higher energy usage by way of the AHU fan running longer and faster to maintain the static pressure in the ducting. Leakages can also impact the air balancing of the system which in turn will lead to hot and cold spots, further impacting the overall system efficiency.

Lowering of System Efficiency : Accumulation of dust and mold on the inner walls of the ducting causes the amount of friction that the air experiences to increase. This causes a drop in static pressure, resulting in the Fan running at a higher speed and consequently resulting in higher energy usage.

Our Process of Maintenace for Ducting System Involves:

Check for Leakages : Leakages can reduce airflow and increase the cost of operation, so the site should be checked for leakages once in six months.

Airflow testing : The ducting system is usually installed with tap-off points that can be used for airflow measurements. A good practice is to measure the airflow at least once a year and compares the data with the design values. Lower flow rates are indicative of higher friction or blocked dampers or air flow passages.

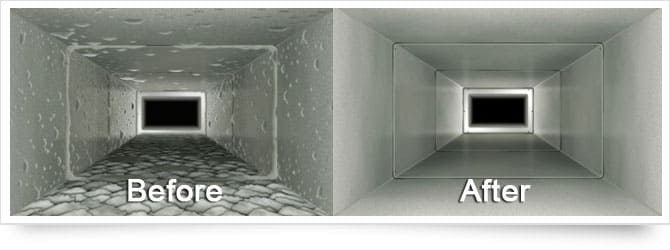

Duct cleaning : We estimate the dust and microbiological levels in ducts by complete inspection of the duct as most of the ducting is concealed. A good practice is to have the ducts inspected at least once in 2 years and then access the requirement for cleaning.

Vibration testing : Higher levels of vibrations in the AHU as well as the system can lead to higher noise levels and also the possibility of fatigue failure of ducting supports and joints. An annual vibration analysis of the key joints and fasteners will help reduce such damage.

Indoor Air Quality Tests : We access the quality of the ducting system to carry out IAQ tests that will bring out the values of various indicators such as particulate matter, microbiological content, etc. in the air. IAQ test should be undertaken at least once in six months and especially when there is a major change in the internal design or if there is an additional headcount in your workspace so that the Air Quality can be maintained accordingly.

Inspection of Vibration Isolators : Our team of engineers inspects the AHU fan that generates vibrations due to imbalance, misalignment, or other mechanical faults which can get transferred to the ducting system and cause ducting system joint failures. The vibration isolators are flexible sections just after the AHU in the supply line and just before the AHU in the return line.

Inspection of Dampers : To allow the flow of air to modify the temperature and to manage the air balancing, dampers are installed at selected locations. The Dampers control the volume of air that flows into a workspace. Modern dampers are electrically controlled using system input parameters in the Variable Air Volume (VAV) type of system. A complete inspection is been done to check any improper flow of the air in your workspace.

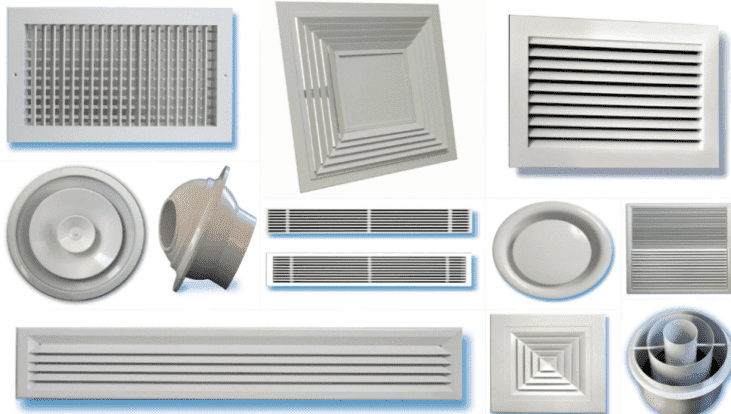

Inspection of Diffusers : The conditioned air exits the ductwork through diffusers. The diffusers help in distributing the air and giving it maximum travel and also minimize the noise as air passes across a varying diameter orifice. Inspection of clogged diffusers is done to prevent the blockage of the airflow in the living space.

Ducting systems play an important role in providing conferrable air to the building occupants. Since all the occupants breathe the air from the ducting systems, any deterioration of the air quality will harm a large part of the workforce. The sick building syndrome is a classic example of what a poor duct system can lead to. Since ducts are always hidden from the user’s eyes, there is often a tendency to postpone or altogether eliminate duct maintenance schedules. This can be damaging to the air quality and also have an impact on the operating costs of the HVAC systems as the system will be operating at a higher design point and lower efficacy due to friction losses in the ductwork. Thus, Our team of HVAC Technicians has a well-developed maintenance plan for your ducting system and we ensure that it is executed as per the manufacturer's guidelines to have a healthy and efficient ducting system.

We offer three types of maintenance for piping systems: routine periodic inspections, physical changes or expansions to a piping system, and unscheduled repairs. Routine periodic inspections are performed to ensure that a system is intact and operating at peak efficiency.

Physical changes or expansions to a piping system are performed to adjust existing installations, add to an existing system, or replace old piping.

Unscheduled repairs are the most pressing and time-sensitive type of maintenance because they are unplanned and, in most cases, require immediate action.

Causes of these repairs can include erosion; corrosion; cracks; leaks; weld failures, such as pinholes and incomplete fusion; and material failure, such as pipe defects. Bearings and impellers also suffer from erosion over time and may need to be replaced. In addition, lines of the pipe may become corrupt and require maintenance or replacement.

We at Om Cooling System have a team of highly skilled technicians who are capable enough to take care of all the maintenance work of your Piping & Ducting System and that too at an affordable price without compromising the quality of work.